Matte Finishing Solid Surface

May 17, 2023 5 min read

Matte Finishing: What to Know

Tools Required:

Random Orbital Sander

80 Micron Pads

(2) per 20sq/ft

60 Micron Pads

(2) per 20sq/ft

30 Micron Pads

(5) per 20sq/ft

Maroon Scotch Brite Pad

(1) per 20sq/ft

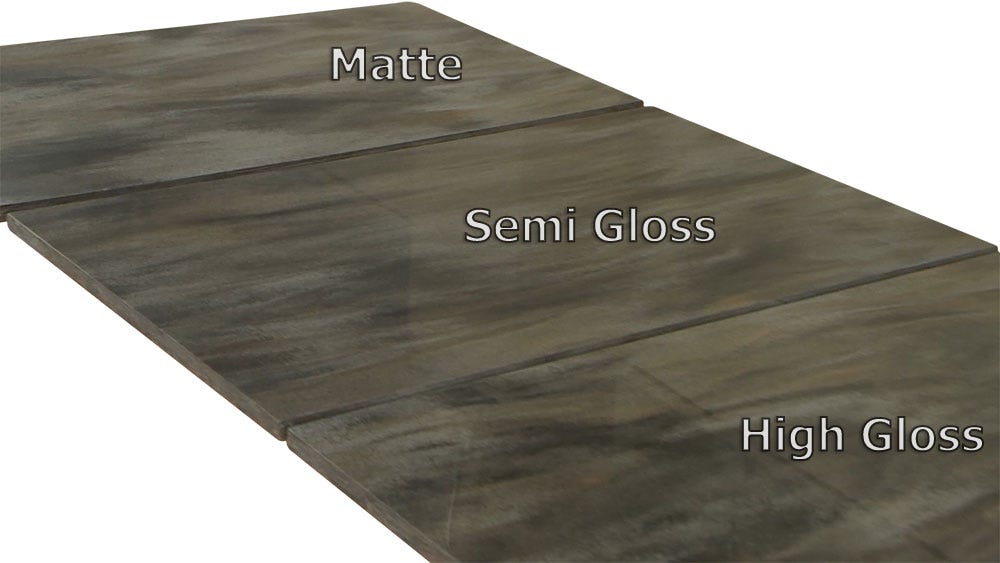

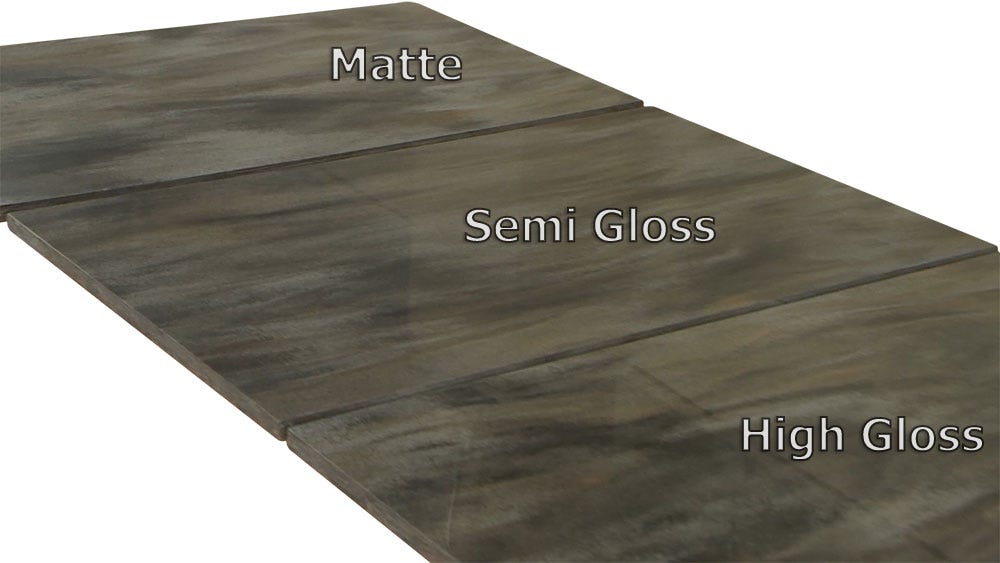

What finish is right for me?

Finish is a major thing to consider with solid surface. A matte finish undoubtedly shows scratches less than semi-gloss and much less than a high-gloss finish. This is especially true of darker colors which tend to show scratches more in general. For high traffic areas a Matte finish is generally recommended. Semi-Gloss finish is an acceptable alternative although you may have some additional maintenance required every few years. High-gloss finishes should only be considered in low traffic areas where aesthetics outweigh durability.

"A matte finish undoubtedly shows scratches less than semi-gloss and much less than a high-gloss finish. For high traffic areas a Matte finish is generally recommended. "

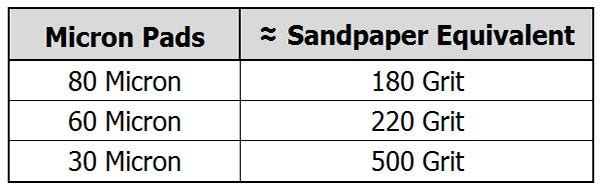

What are micron disks and how does this compare to regular sanding pads?

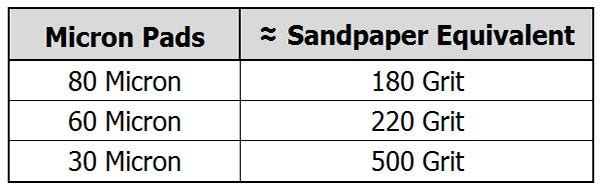

Micron sanding disks have have consistent grit across the entire sanding pad. With regular sandpaper, the grit is inconsistent. If you purchase and use 220 grit sandpaper, none of the grit is larger than 220, however many could be of varying smaller sizes. This inconsistency can cause swirls in sold surface. For this reason we recommend and exclusively use micron pads. (Micron pads are available in the supplies section of our website.) If you prefer to use regular sanding pads instead, to the left is a rough conversion chart so you can still follow the instructions below.

Adding a Matte Finish to Solid Surface

1. Check to see if the surface is free of any scratches or defects caused during transportation, handling or fabrication. If there are no scratches or defects, you can skip step two and begin with a 60-micron disk.

2. Using an 80-micron abrasive disk, sand the entire top to a uniform finish using your orbital sander. Be sure to overlap sanding strokes by at least ½ the pad diameter and cover the entire surface. Once complete, wipe down the surface and inspect for leftover scratches and a uniform finish.

Key Tip: Most people recommend sanding in an up-down, left-right motion. This is certainly acceptable, it sometimes produces a "railroad" effect if you're not careful. In our facility, we generally train employees to use random swirls while making sure to cover the entire material evenly. Either technique works, just take care not to over sand any one area.

3. Using a 60-micron disk, sand the entire top to a uniform finish. Typical to step two, be sure to overlap your sanding strokes.

Key Tip: With each successive sanding pad, the goal is to sand until you have removed the scratches from the previous grit (i.e. While using the 30 micron disk, you will know you are finished once you have removed all of the scratches made by the 60 micron disk.)

4. Re-sand the top with the 30-micron disk and repeat the cleanup procedure. Inspect top once again

5. Wipe the top down with a wet cloth, then buff with a maroon Scotch-Brite pad. This will leave an attractive matte finish.

Key Tip: To effectively check for a uniform finish during sanding, install low-angle lighting behind the work station